Recently this article featuring a 3D printed door handle was published, showcasing the potential of ‘smart structures’, 3D printed with no moving parts.

This technique is very similar to something I’ve been working on in my research in unit cells and auxetics. In this blog I’ll explain how these two concepts can be utilised to create unexpected properties. I’ll also feature some of my original auxetic unit cell designs.

– Unit Cells –

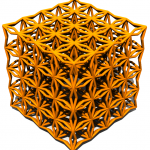

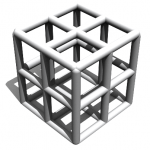

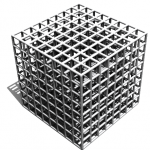

Just like the arrangement of cells in your body, unit cells can be used to best mimic the non-uniform nature of tissue. Like lego blocks, unit cells can be designed to inter-connect to form lattices or aggregations of unit cells. Unit cells can be designed to have differing mechanical properties, allowing greater control over stiffness, strength, flexure, movement. Other characteristics useful in tissue engineering such as flow perfusion and biodegradability can also be controlled with this approach. Just like in the door handle above, different unit cells can work together to deliver extra ‘smart’ functionality. Unlike the two-dimensional flexure of the door handle, my unit cells are designed to flex in three dimensions.

– Auxetic Materials –

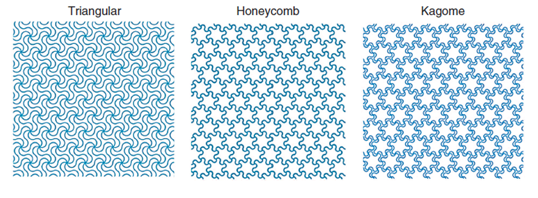

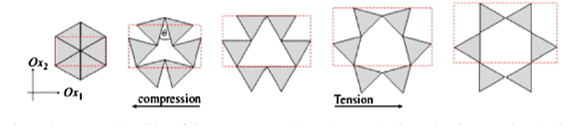

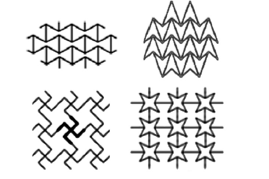

Auxetic materials, or materials with a negative poisson’s ratio, have properties counterintuitive to the behaviour of most materials we come across in daily life. When a rubber band is stretched, it becomes thinner at the centre point of flexure. Auxetic materials, when stretched, become thicker. During physical stress, auxetic materials contract to form a stiffer area at the site of impact. This auxetic effect can be created through the usage of ‘re-entrant’ structures, like the early two dimensional auxetics below designed by Lakes et al.[1] , curved designs by Jang et al. [2] and rotating triangular structures by Grima et al. [3], respectively.

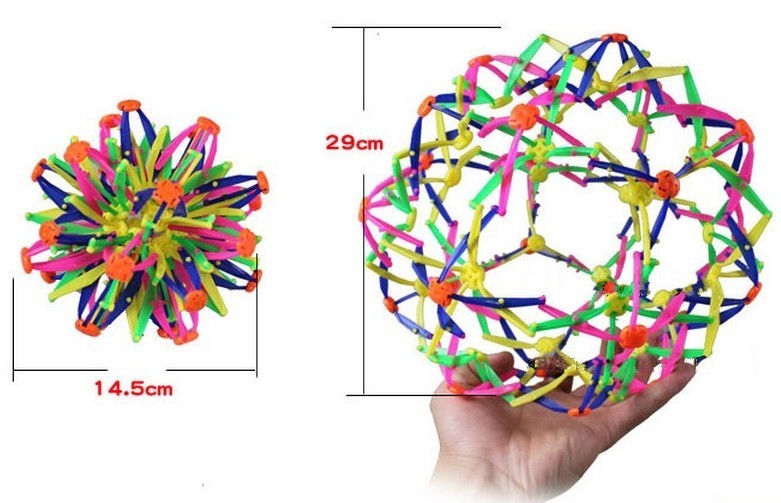

They also feature in the popular Hoberman expanding sphere kids toy.

Auxetics also possess high energy absorption properties [4, 5], and are flexible, yet strong, making them an ideal candidate for tissue engineering purposes.

Due to the unique properties of auxetic materials, there is a vast potential of applications including defence, sports, aerospace and biomedical. Companies such as Nike [6], Rolls Royce [7], NASA [8], Blast Control Systems [9], Apple [10] and Boeing [11] have recently filed patents for auxetic products, demonstrating the potential of further innovation with an auxetic approach. Within the medical industry, auxetic bioprostheses such as intraluminal implants [12], annuloplasty [13] and knee prosthetics [14] further attest to these properties.

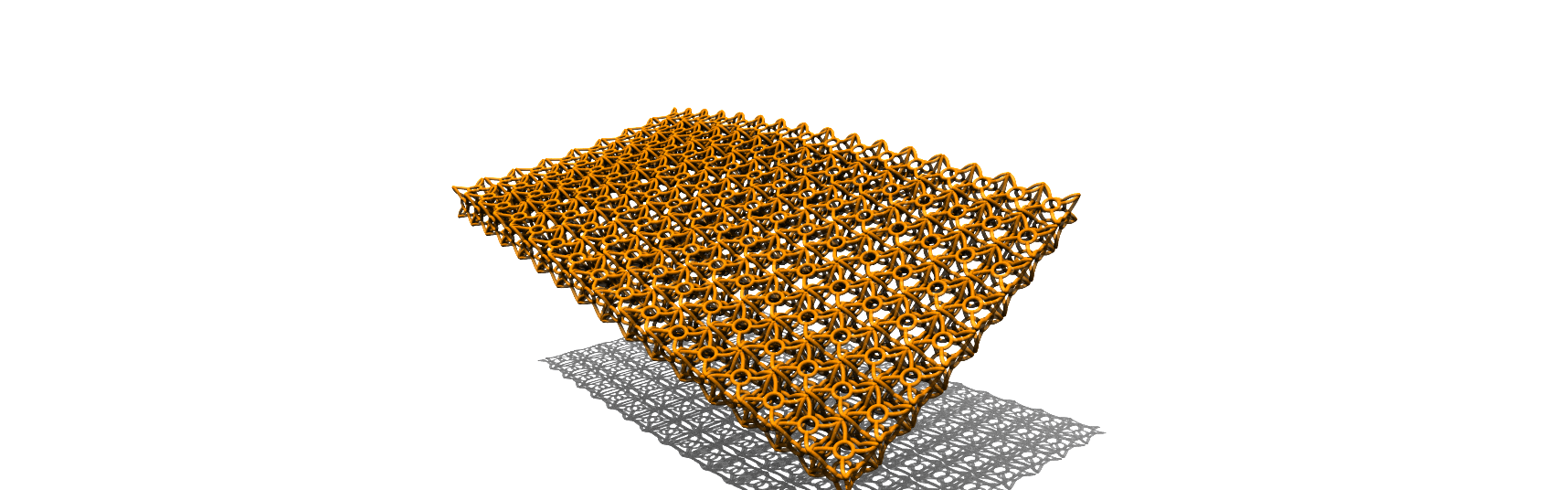

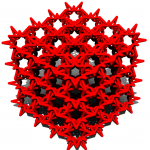

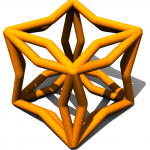

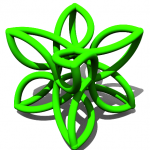

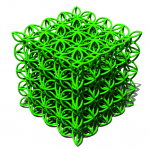

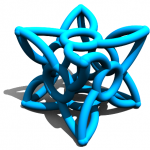

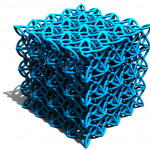

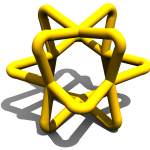

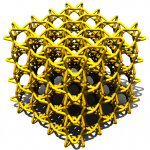

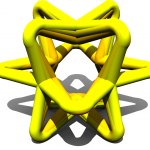

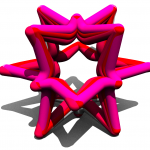

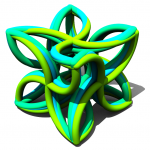

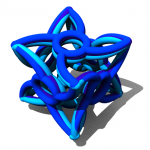

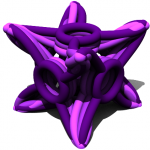

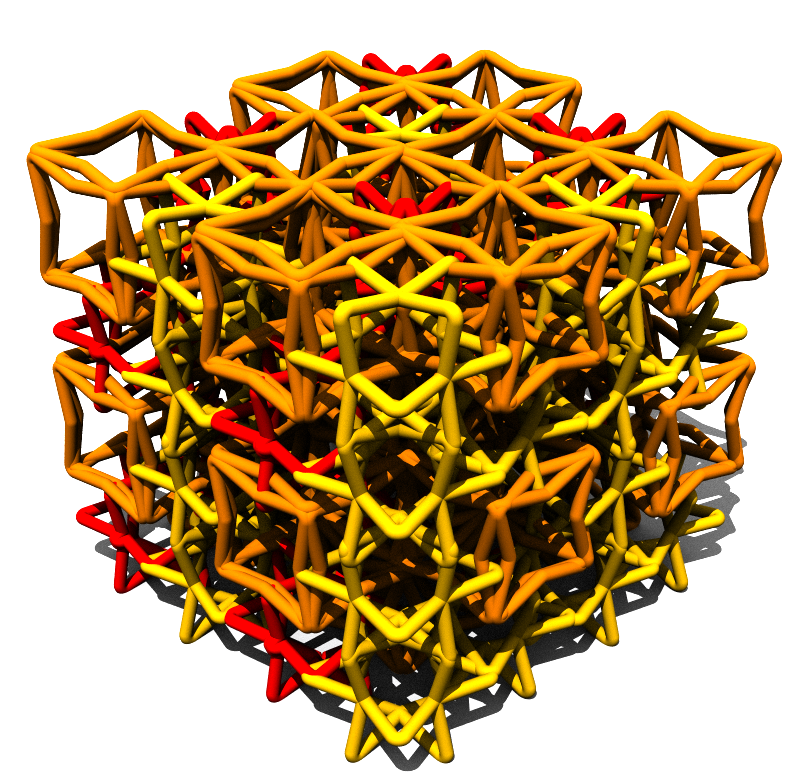

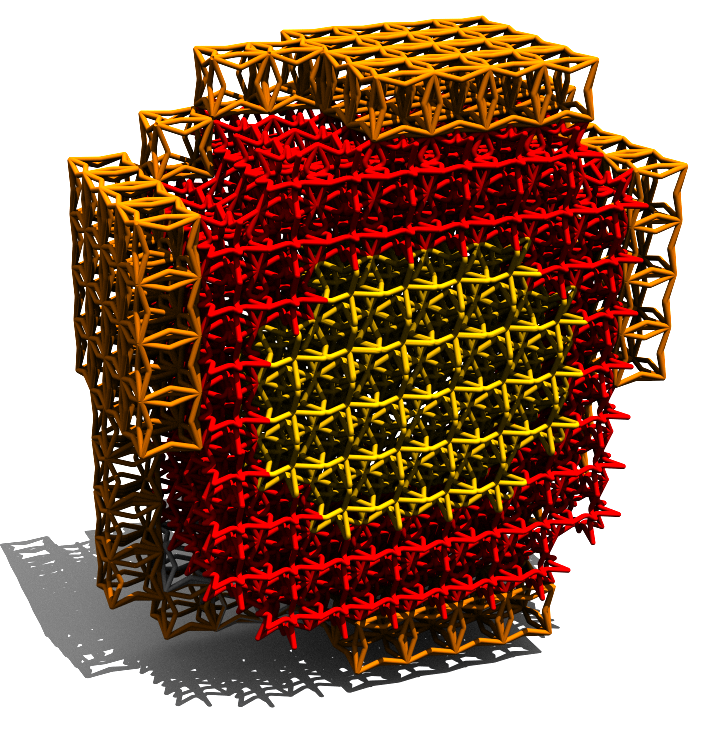

I designed seven different auxetic unit cell structures which could be arranged in lattices to mimic tissue. Each of the seven had three angle variations of the structure (shown in the colourful superimposed composites) and a non-auxetic, box-shaped control structure. When cells are grown in the lab, mimicking the desired tissue mechanical properties is paramount in achieving the desired tissue, especially in growing fat and bone cells [15, 16]. Therefore, developing biodegradeable scaffolds which replicate the stiffness of actual tissue is very important.

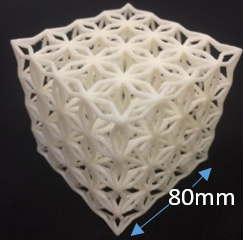

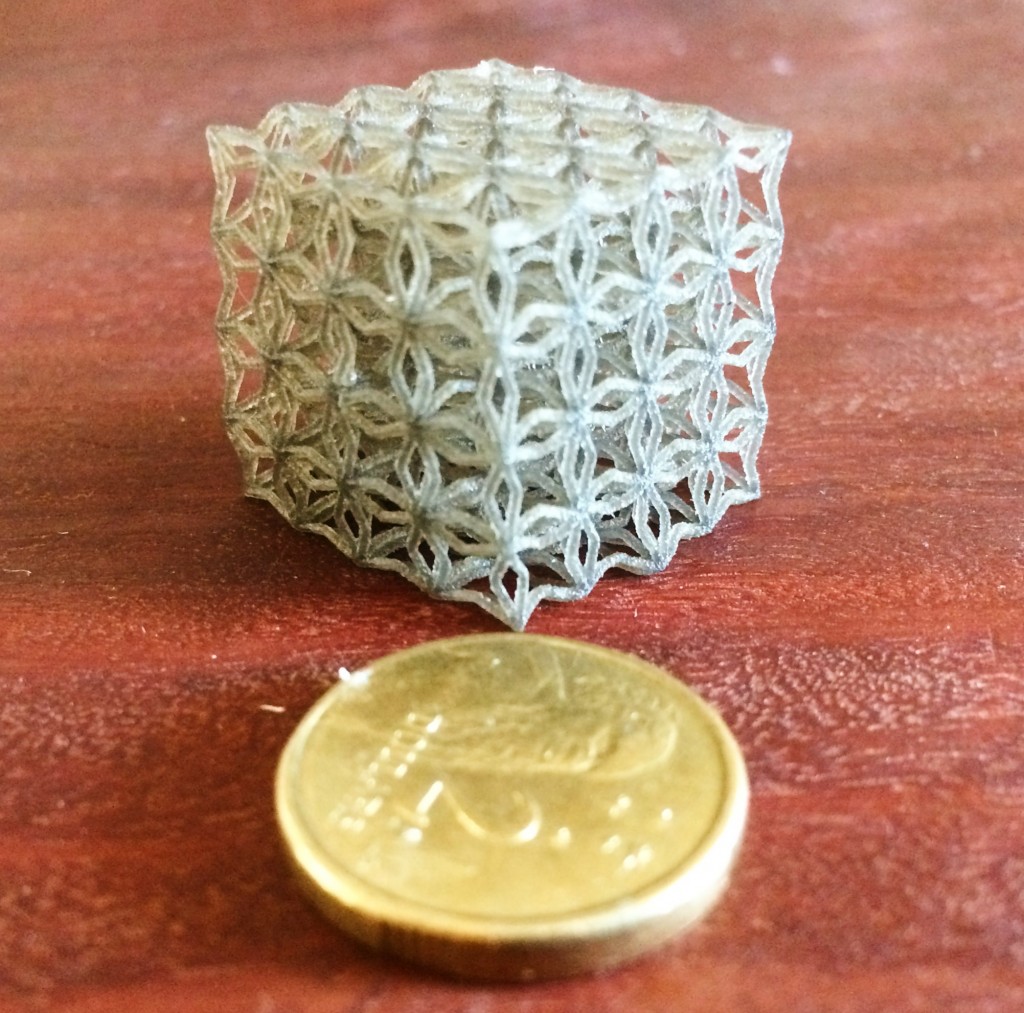

I also had these models 3D printed, as seen below. The models are optimised to provide a balance between structure and porosity to allow cell growth in the open space and also support the cell growth. This means the unit cells are quite spindly and delicate, making them difficult to print on desktop machines but they can be created in a larger size or on higher end resin and powder based machines.

Currently, much of our 3D printing capabilities do not allow us to use these at a preferable size for implants in the desired material, but things are moving quickly. I’m putting these up online and dedicating to the public domain to allow others to create, use and modify my models freely. You can see and download my prototype unit cells here.

If you’re a researcher in this space, feel free to contact me and I can put you in touch with other researchers in this space to collaborate.

References

- Lakes, R., Foam structures with a negative Poisson’s ratio. Science, 1987. 235(4792): p. 1038-1040.

- Jang, K.-I., et al., Soft network composite materials with deterministic and bio-inspired designs. Nature communications, 2015. 6.

- Grima, J., A. Alderson, and K. Evans, Auxetic behaviour from rotating rigid units. Physica status solidi (b), 2005. 242(3): p. 561-575.

- Alderson, A., et al., Modelling the deformation mechanisms, structure–property relationships and applications of auxetic nanomaterials. physica status solidi (b), 2005. 242(3): p. 499-508.

- Scarpa, F., et al., Auxetic compliant flexible PU foams: static and dynamic properties. physica status solidi (b), 2005. 242(3): p. 681-694.

- Cross, T.M., et al., Auxetic Structures And Footwear With Soles Having Auxetic Structures. 2015, Google Patents.

- Bianchi, M. and F. Scarpa, A method of manufacturing a foam showing a gradient poisson’s ratio behaviour. 2015, Google Patents.

- Kim, J., et al., Polyaniline/carbon nanotube sheet nanocomposites. 2014, Google Patents.

- Rossow, R. and C. MCCONNEL, Blast control blanket. 2014, Google Patents.

- Casebolt, M. and R. Murphy, Adhesive Stack with a Central Shear Layer. 2013, Google Patents.

- Liguore, S.L. and J.M. Montgomery, Systems and methods for reducing noise in aircraft fuselages and other structures. 2013, Google Patents.

- Roels, T. and P. Verschueren, Patient-specific intraluminal implants. 2014, Google Patents.

- Burriesci, G. and G. Bergamasco, Annuloplasty prosthesis with an auxetic structure. 2009.

- Sabatino, A., Auxetic prosthetic implant. 2014, Google Patents.

- Engler, A.J., et al., Matrix elasticity directs stem cell lineage specification. Cell, 2006. 126(4): p. 677-689.

- Young, D.A., et al., Stimulation of adipogenesis of adult adipose-derived stem cells using substrates that mimic the stiffness of adipose tissue. Biomaterials, 2013. 34(34): p. 8581-8588.